设计验证使用纤维选择翼变形ic Distributed Sensing

Josiah Fee

In response to government initiatives such as the FAA’s Continuous Lower Energy Emissions and Noise (CLEEN) program, aircraft manufactures are working on new technologies to increase efficiency and reduce noise. The design of a morphing wing leading edge is one method that can be used to accomplish these goals. Traditionally, slats are used to increase the angle of attack of a wing for take-off and landing. Unfortunately, since there is a gap between the slats and the wing, they produce a substantial amount of turbulence and noise. With a morphing leading edge, the angle of attack is increased smoothly by deforming the wing via internal actuators. This gives the air a continuous surface to flow over, which helps decrease turbulence and noise production. The morphing wing’s leading edge is made with an elastomeric material that must be sufficiently compliant to change shape to a specific geometry during landing and take-off, and yet, rigid enough to maintain that geometry when subject to loads associated with inflight conditions.

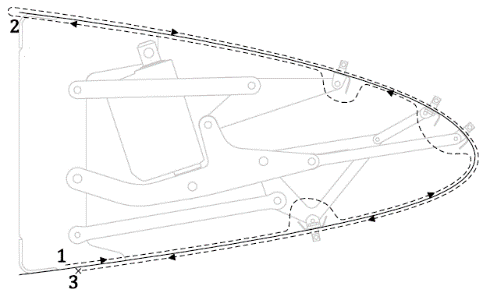

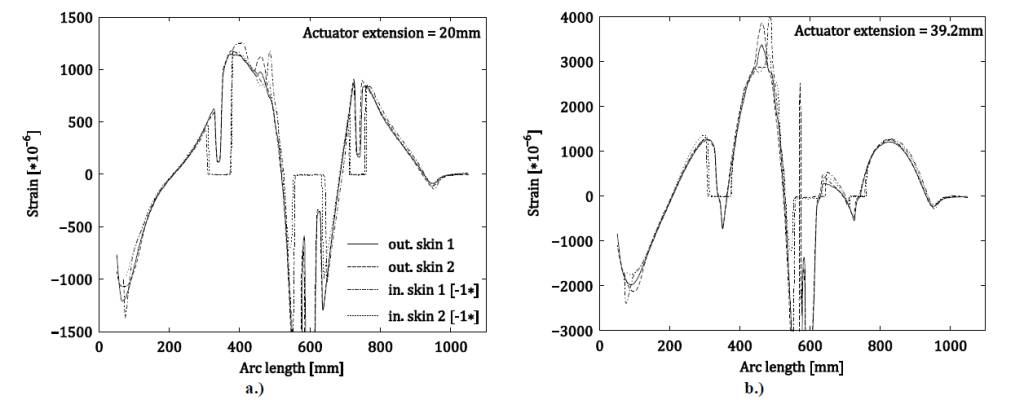

In a paper published at the recent AIAA SciTech Conference, researchers from Delft University of Technology and the Fraunhofer Institute for Building Physics designed, manufactured and tested a functional, seamless, morphing leading edge demonstrator built with an actuator mechanism and an aero-elastic airfoil skin. An analysis of predicted strain was done using a (FEM) analysis tool and results were compared to experimental data acquired with Luna’sODiSIB distributed fiber optic sensing system. In order for a morphing leading edge to be feasible for safe flight, it is essential that the morphing is caused by bending of the airfoil as opposed to stretching. It was therefore important for the researchers to measure a continuous strain profile along the perimeter of the airfoil. Fiber optic sensors were lined along the inside and outside of the airfoil in order to differentiate between axial and bending strains. Strain analysis showed that once the inner strain was negated, the strain values were nearly identical along the inside and outside of the foil. This indicated that wing morphing was in fact due to bending, validating their design principles.

These types of measurements are not practical with traditional point sensing methods that cannot provide the degree of resolution needed by design engineers who work on cutting edge technology with a high degree of unknowns. The ODiSI B, based on Rayleigh Backscattering technology, is capable of using a sensor constructed of unaltered fiber optic cable and can provide high density strain measurements down to 1.28 mm spatial resolution and with a 20 meter maximum sensing length. The ODiSI B has four user selectable operating modes that optimize sampling rate, sensor length and spatial resolution according to the test requirements. Data captured with the ODiSI B can be viewed real time or captured for post processing and data analysis. For more information the full paper can be accessedhere. Reference: J. Sodja, M. Martinez , R. de Breuker, J. Simpson,“Experimental Evaluation of the Morphing Leading Edge Concept”, Proceedings of the American Institute of Aeronautics and Astronautics Science and Technology Forum 2015, June 2014.