Luna和Shell GameChanger创新了新的地下传感器

Luna Innovations开发了一个新的概念,与Shell的GameChanger™早期技术计划使用Luna光纤传感解决方案测量地下岩石的原位应力。

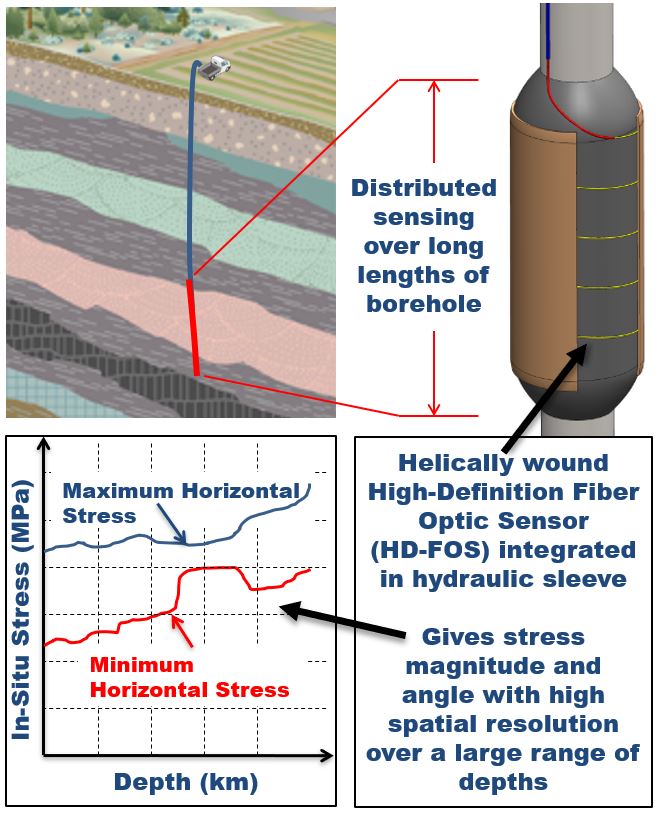

新概念,一种连续水平的原位应力记录器(CHISL),使用LUNA的ODISI®产品来获得诱导的微骨折和钻孔变形的直接,高分辨率应变测量。然后,新的算法在钻孔处处理应变测量以估计原位的最大值和最小水平应力及其方向。

为什么这件事?Businesses that rely on underground operations, like the petroleum and geothermal industries, must have accurate estimates of in-situ stress (which is the existing pressure underground before a hole is drilled). This affects drilling, surveying, and fluid injection (hydraulic fracturing, water flooding, CO2 sequestration) as well as phenomena such as fault re-activation and induced seismicity.

行业的想法是什么?“可靠的压力估计对于石油和天然气行业的许多应用至关重要。例如,液压压裂的成功强烈取决于所产生的骨折高度,这又通过深度的应力变化强烈控制。Luna的技术将允许具有前所未有的解决方案,与水力压裂过程非常相关的压力深度配置文件,“壳牌的地质力学主题专家Alexei Savitski评论说:“今天没有访问这些关键信息。最大水平应力是最不确定的地下特性之一。它从其他数据推断出来。但CHISL将允许显着降低这种不确定性,这对于评估故障重新激活和诱导地震性的风险至关重要。

“Working with Luna on this technology fits very well with the GameChanger mandate,” explains Haiyong Cai, the GameChanger sponsor for this project. “The program supports Luna to derisk the early development of this novel stress-measurement technology to the proof-of-concept level. It also engages Shell to put forward use cases where accurate, reliable stress measurements may drastically improve the bottom line.”

是什么让Luna的Chisl传感器独特?It integrates fiber optic sensors into a flexible hydraulic sleeve, which applies pressure to a borehole wall until small longitudinal fractures are formed. Unlike hydraulic fracturing, where fluid flows into the fractures and causes them to grow in length away from the borehole, CHISL does not allow the fluid to flow into the induced fractures. The CHISL sensor will provide new kinds of data that can be used to increase safety, production efficiency and optimization of future subsurface engineered systems. Future field operations using a ruggedized sensor could provide measurements for unprecedented lengths of boreholes and in less time than traditional hydraulic-fracturing techniques. Apart from the stress profiling of rock formations for planning of hydraulic fracturing, other applications include caprock integrity sensing for oil wells and optimized drilling of complex oil wells.

解释CHISL传感技术(专利申请中)

Embedding HD-FOS sensing fiber in a helical pattern allows for precise measurement of radial and axial strain as the hydraulic pressure inside the sleeve is increased. The continuous measurement of strain around the circumference and down the depth of the hole provides new types of data that have previously been unavailable, such as fracture initiation and evolution in real-time. The methodology to measure in-situ stress is shown in Figure 2.

Methodology of Distributed Fiber Optic Sleeve Concept

- Place sensor uninflated at the desired depth. This allows for sufficient clearance to position it within the borehole.

- 将传感器套管加压,直到它径向扩展以符合钻孔壁的轮廓和界面。此处获取应变测量,并成为将比较在更高压力下进行的基线签名。基线测量还可以提供有关钻孔形状的变化的信息,而预先存在的骨折的存在。水平骨折将显示为沿着螺旋传感器路径的应变测量中的单一峰值。

- 增加传感器内的液压以产生岩壁的弹性变形,因此可以进行弹性模量的测量。该测量可以作为深度的函数以及由局部应变轮廓识别的钻孔壁的函数识别模量(由于变化的材料)的变化。

- 将液压增加到第一裂缝发生的点。在理论上,这种骨折的方向应垂直于最小水平应力,Sh。由于套筒中的纤维的螺旋结构,所测量的应变将表现出周期性峰的图案;它会在多个绕组上与骨折相交。假设传感器的方向是已知的,第一峰值从传感器原点的距离指示第一裂缝发生的角度取向。骨折骨折的轴向长度可以从观察到的峰的数量和它们的相对距离下纤维来确定。与传统压裂技术相比,这是额外的好处是在加压过程中立即观察到裂缝,而不是使用印模包装机或视觉后工艺。

- 提高压力直至发生第二裂缝,这与最大水平应力有关H。相对这个secondar孵蛋的方向y fracture can be calculated from the phase between the first series of peaks and the new series of peaks. The measurement technique can accommodate additional unintended fractures or non-perpendicular fracture directions because the high-resolution strain data will resolve these features. Variations in fracture magnitude and angular orientation, which corresponds to in-situ stress, may change along the depth of the borehole, and the proposed technique would allow those variations to be observed with high resolution. The resulting stress versus depth that is calculated from the technique would be plotted as seen in Figure 1.

在单个位置执行完整测量后,传感器套筒中的压力降低。裂缝将关闭,并且套筒可以自由地定位在下一个位置。在此过程中,所有液压流体仍然包含在传感器内。因为没有液体损失并且传感器套筒的外径可以小于66毫米,因此预计执行测量所需的所有设备将适合在公用事业车上(液压泵,传感器/电缆阀芯,流体,仪器电子和计算机储存器)。

Chisl概念证明实验

在局部石灰石采石场钻出一个浅的HQ钻孔,以证明CHISL原型的骨折感测能力(图3)。使用核心样品的巴西圆盘测试测定岩石的拉伸强度为3,100psi。

An impression packer was used before and after CHISL operation to verify the fracture state pre- and post-test. In the measurement described here, a pre-existing horizontal fracture was the only impression recorded before the test.

随着CHISL组件膨胀,在钻孔壁的应变图中可见相同的水平骨折,如图4所示。图的X轴沿着孔的深度,而Y轴是圆柱形CHISL传感器的圆周周围的极角。颜色图表示在嵌入式光纤传感器内的每个位置观察到应变电平。

进一步加压CHISL传感器,双翼骨折出现在水平骨折以下和高于水平骨折以下,但在不同的角度和施加到钻孔壁上的不同压力下,如图5所示。

该图中的颜色图表示相对于压力增加的应变的导数,并且有助于识别随着压力升高的压力快速生长的应变位置。水平分隔下方的裂缝发生在90°和270°处,在2,500psi的较低压力下发生,而水平分区上方的形成在3,700psi的压力下在180°和330°处破裂。这证明了分布式感测概念的力量。在1M传感区域内有足够的空间分辨率来检测各个裂缝开口,它们的长度和沿着孔的深度的应力取向的变化,甚至同时测量两个不同的形成。

用CHISL传感器进一步加压钻孔,直至在4,900psi下发生双重断裂,如图6所示。在270°处的新骨折在源自较低压力下的双翼骨折之间大约90°。还观察到,330°的断裂减少,而0°的新骨折开口。据理论,这种新的骨折与岩层中的最大原位应力有关。

Relating these local measurements to the far-field stress state is the next critical step, and Luna’s team of partners has developed an algorithm to calculate the far-field stress state from the high-definition fiber optic sensor data. Visualizing these fracture evolutions with such spatial resolution and in real-time is unprecedented.

该实验证明了CHISL传感器具有创造,测量和可视化对应于最小和最大水平应力的裂缝的可能性。部署时,该技术将以无与伦比的一致性和深度分辨率提供关键测量,允许更安全,更高效的操作。

Shell Gamechanger™程序与公司合作,通过各种公司进行高影响力能源技术。超过20年,它有助于许多启动,以获得他们需要成长的资金和专家支持。近年来,GameChanger™在战略上专注于技术开发,加快壳牌的能源转型努力,包括与各种孵化器,学术机构和国家实验室形成战略联盟。

阅读news release在CHISL传感器或联系Luna.想要查询更多的信息。